Optimising data clarity in mine reporting software

Pitram is a fleet management and management reporting solution that records, manages and processes mine site data in real-time. Through mine reporting software that converts data into meaningful information, Pitram provides a thorough overview of a mine site’s activities and increases managerial control over operations. Greater control allows key personnel to increase production, lower production costs, and improve safety and business intelligence capabilities.

Comprised of intuitive asset, personnel and material tracking, safety, grade and stockpile management, real-time view, planning, optimisation, reporting and analytics capabilities, Pitram offers mining operations of all sizes a scalable and flexible solution that can be adapted as a site grows.

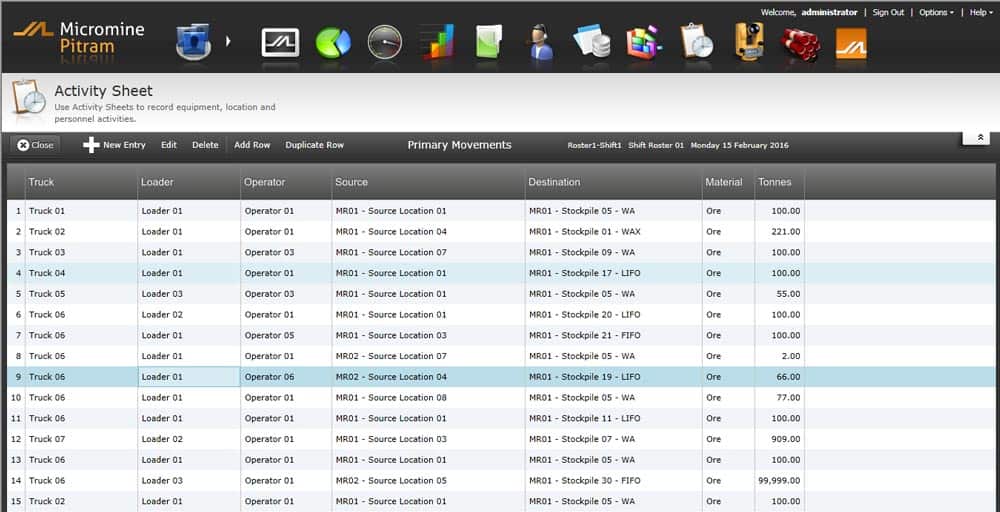

Suitable for underground and open pit mining operations, Pitram- Activity Sheet is a manual reporting solution, which utilises a web platform to deliver management data, material movement information and performance reports related to equipment and personnel. Users manually enter data into operation dashboards at the end of every shift to populate a production database. This data provides key personnel vital information which is presented in report form so that informed decisions about the site’s current and future activities can be made.

Scalable Reporting Solutions

Pitram is ideal for smaller operations that require the essentials of a mine control application, but don’t want the expense of features that aren’t going to be utilised. Alternatively, as an entry level solution, it is often the application of choice for larger operations that want to introduce Pitram through a phased implementation approach, or developing mines that have plans for growth and anticipate that their reporting requirements will become more complex.

Reporting capabilities:

- Data related to timesheets and onsite activities is manually entered into Pitram Report via operation dashboards at the end of every shift by personnel

- The data entered into the operation dashboards is collated via the web platform and turned into meaningful information, presented to key personnel in report format

- Operator Reports provide a high level overview of activities undertaken during shifts

- The Grade Control module ensures that material flow and grades are tracked and reconciled throughout the operation

- Through validation capabilities, users can check data against parameters, highlighting mistakes or inconsistencies

Benefits:

- Key personnel are provided greater control over the ore, resulting in increased ore security

- Major time delays are identified, allowing management to re-allocate resources or change plans accordingly

- Routine reports are automatically generated, saving personnel time

- Reduced data handling, resulting in fewer mistakes and reduced personnel hours

- Improved efficiency and resource allocation via the reduced cost of data extraction and manipulation, including end of month reconciliation

Customising your mine reporting software systems

Because all mining operations are different and have varying needs, Pitram is a flexible solution that can be adapted according to an operation’s specific requirements. This means that no matter how large or small an operation is, where the site is located, or what commodity is being mined, Pitram is suitable for all operations. Pitram uses the same production and reporting database for its entry level Pitram solution as it does for its high-end automated Pitram solution. The value in the software, training, and the work invested in implementing the original solution is therefore retained when an operation upgrades to a more advanced Pitram solution.

Learn more:

Explore data capture in our mine reporting software systems: